A floating floor can have three functions, or a combination of them, depending on the end goal in the design of the building:

Increase the airborne sound insulation properties of the structural floor. For example: music rooms, rehearsal rooms, recording studios, cultural centers, etc.

An increase in the vibration isolation properties of a structural floor containing machinery that generates vibrations. For example: floors under generators, HVAC units, transformers, pumps, and other equipment for building installations.

- sound insulation effect

Increase in sound insulation properties of impact structural flooring. For example: floors of rooftop bars, dance halls, gymnasiums, above classrooms, corridors, etc.

What is the lifting system for floating floors?

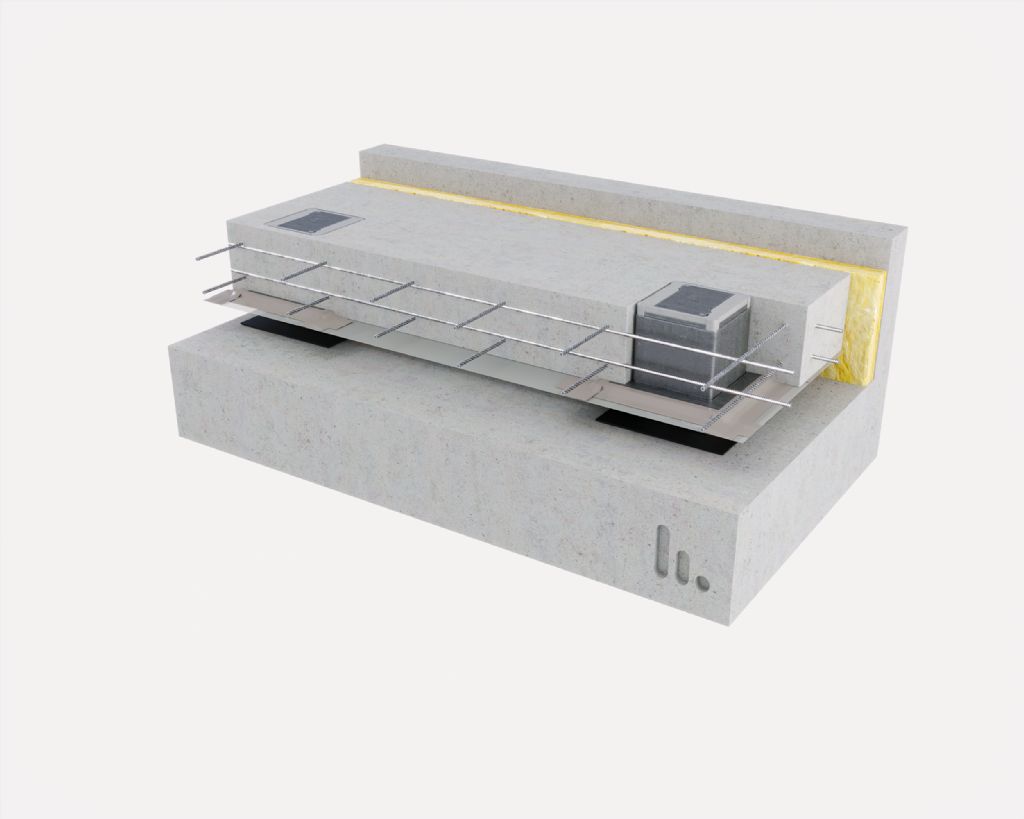

As the name implies, crane floating floors are insulation systems that use boxes embedded in the concrete slab which, after the concrete has cured, is raised to create an air cavity, thus completely separating the floating floor slab from the structural elements. the earth. The floating floor is only supported by the insulators in the boxes, which are steel springs or rubber pads. These systems are recommended when reduced transmission of noise, vibration or shock is required.

Hoist or hoist systems, originally designed and used to insulate industrial facilities, are now widely used to isolate technical rooms, areas with high acoustic requirements, and some sports facilities.

Why do we use the crane for floating floors?

1. Ensures that the floating floor is completely separated from the structural floor

Removable floating floors are a reliable way to create an air gap between the floating concrete floor and the supporting floor. These systems greatly reduce the risk of acoustic bridges between the two plates, as any contact is cut off when the floating floor is raised and no debris can remain in the air cavity.

Some of these systems have a very high load capacity, which means that on the one hand fewer support points are required, and on the other hand it is possible to have larger distances between the supports, with the interesting result that the system is more competitive in price terms than many believe times.

2. Suitable for both negative and positive isolation

An acoustic floating floor can be used with jack boxes to isolate noisy areas, such as rooms of mechanical equipment, from adjacent rooms, or it can be used to isolate a room sensitive to noise and vibrations from external sources. These forms of active and passive insulation make openable floating floors a value-added solution to any acoustic design.

3. The overall construction height of the system is independent of the thickness of the insulators, allowing for thin-floor construction.

In the crane system, the spring or rubber pad is located inside the metal case, so its thickness has little effect on the overall height of the system. Besides the fact that it is a system without formwork, this solution allows the installation of an acoustic floating floor of limited thickness.

With the winch floating floor, the overall height can be changed without the need to change the thickness of the steel spring or elastomer. This avoids the risk of increasing the natural frequency of the system.

4. It can be accessed, checked and replaced

There are lifter floating floor systems that use always accessible boxes that can be opened after installation. This type of system allows the customer to check, adjust and replace springs or elastomers if necessary (eg changing loading conditions).

5. Unnecessary formwork

This type of floating flooring is the only detached support system that does not require lost formwork. Since concrete is simply poured around the metal boxes and onto a polyethylene sheet over the structural floor, there is no need for concrete pouring. By not using formwork, the distance between the supports does not depend on the bending strength of the formwork and therefore the distance between the supports is determined by the thickness of the floating floor and the reinforcing mesh, as well as by the load-bearing capacity of the insulators themselves and the metal boxes in which they are located. Additional point/linear loads on the floating floor can be easily accommodated by adding additional boxes.

6. Available with springs or elastomers

Compressible floating floor systems are available with springs or elastomers as insulators at normal frequencies of 2.5 Hz and 6 Hz respectively.

The choice of insulator type depends on the requirements of the project.

7. Easy to install and economical

Crane floating floors are very easy to install, as they do not require modification in areas with unusual lines. Once the boxes are placed in accordance with the requirements specified in the project, it is a matter of installing the reinforcing mesh and pouring the concrete. Concrete flows around the boxes and in all corners, which significantly saves time during installation.

This type of floating floor system contains few parts, which makes installation much faster and reduces the risk of installation errors and costs related to potential subsequent repairs. Moving the few parts and small volumes to be moved also means lower transportation costs, which also reduces the environmental impact.

8. Adjustable air cavity

Overhead crane floating floors typically use steel or cast iron boxes embedded in reinforced concrete and subsequently raised with cured concrete to create the required air gap. This method of lifting not only reduces the risks of acoustic bridges, but also gives the client maximum flexibility.

Strafflower Jacob R

Stravifloor is CDM Strativec’s line of high performance floating floors. Stravifloor Jackup-R is a Jacob flooring system that uses reinforced boxes and replaceable insulators embedded in a floating concrete slab.

Stravifloor Jackup-R boxes allow easy adjustment of final floor height, as well as replacement of insulators, should space use or loading conditions change in the future. The insulators remain accessible and can be replaced even after concrete has been poured, so that they can be easily inspected in the future. However, replaceable and inspectable acoustic floor systems are viewed by the market as systems with lower acoustic insulation (airborne noise) than conventional floating or non-replaceable flooring systems.

In order to measure the acoustic performance (airborne sound reduction and acoustic insulation against sound effect) of Stravifloor Jackup-R systems, and to identify the factors that could affect their performance, CDM Stravitec decided to invest in a test campaign (carried outside BRI, a recognized by implementing the Decree-Law issued on January 30, 1947).

In this study, measurements were made regarding the following variables:

1. Thickness of floating concrete slab: 100 mm (4 in) and 150 mm (6 in)

2. Type of insulators: springs and elastomers

3. Different heights of air cavity

4. 50mm steel lid installed on the top of each box

5. With and without mineral wool in the air cavity

Test campaign results

Jackup floating floors in general and the Stravifloor Jackup-R system in particular are proven to provide excellent acoustic performance. During the trial campaign, it became clear that the crane’s floating floors are ideal for reducing airborne noise and isolating impact sound, contrary to what is generally assumed in the market.

The holes made in the floating concrete slab by lifting systems that allow inspection and replacement of the insulators do not significantly affect the overall performance of the insulating solution. Adding a 50mm steel cover on top of each box didn’t make much difference to the sound insulation. With or without a steel housing, the Stravifloor Jackup-R system efficiently isolates shock noise and reduces airborne noise transmission. The added benefit of being able to inspect and replace the mounts at any time justifies the marginal difference in vocal performance.

With and without variable load

The insulators are designed according to the expected load. The insulators used in a winch floating floor system should not be too rigid or too soft as this may degrade the performance of the acoustic system. When choosing the type of insulator, the weight of the floating floor must also be considered in order to achieve the desired natural frequency. The stiffness and type of insulator used, elastomers or springs, allow for a custom design with optimum acoustic performance.

To mimic the variable load, sandbags were placed in the areas between the boxes. In addition, in the transition from a plate with a thickness of 100 mm to a plate with a thickness of 150 mm, the type of insulator was adapted to the loading conditions. Natural elastomers were replaced with extra-rigid pads and when springs were used, the type and number of springs were modified in boxes placed on the corners or in the center of the floating plate. Boxes installed in the corners have a smaller impact area than those installed in the middle and therefore bear less load. From this it can be concluded that when the insulator is designed according to the expected loads, it is possible to improve the sound insulation at low frequencies, which can be explained by the low resonance frequency of the insulators.

Low sound transmission

Taking into account the limitations of the test chambers used in these tests, we can also conclude that airborne sound insulation measured at high frequencies is limited by low sound transmission. The results showed that when using elastomers on a concrete floor with a thickness of 100 mm and 150 mm, a higher impact noise level (+ 2 dB) is achieved for a slab of 150 mm thickness. This small difference is due to the type of elastomer used in both configurations and its natural frequency. The 150 mm thick slab was tested with higher natural frequency insulators than those used during testing with a 100 mm thick concrete floor.

When comparing the two arrangements, and especially their insulating properties against airborne noise, there is a noticeable difference of 4 dB in favor of the thicker floating panel, due to its greater mass.

Air cavity and mineral wool

During the test campaign, the same floor system was tested with different air cavity heights, so that we can conclude that the air cavity height has a primary effect on airborne sound insulation. After adding mineral wool, as an absorbent material, the results are greatly improved because the formation of standing waves in the air cavity is reduced to a minimum.

elastomers or springs

Stravifloor Jackup-R is available with elastomers or springs as insulators. Comparisons between systems using springs or elastomers show that the choice of insulator type is directly related to the target natural frequency of the system. The required natural frequency can be a design requirement, depending on the natural frequency of the building elements or the frequency of excitation. Similar levels of acoustic insulation (IIC/Ln) and airborne sound insulation (STC/Rw) can be achieved with both elastomer and spring-loaded floating concrete floors.

“Total coffee specialist. Hardcore reader. Incurable music scholar. Web guru. Freelance troublemaker. Problem solver. Travel trailblazer.”

More Stories

GALA lacks a chapter on e-health

Weird beer can taste really good.

Planets contain much more water than previously thought