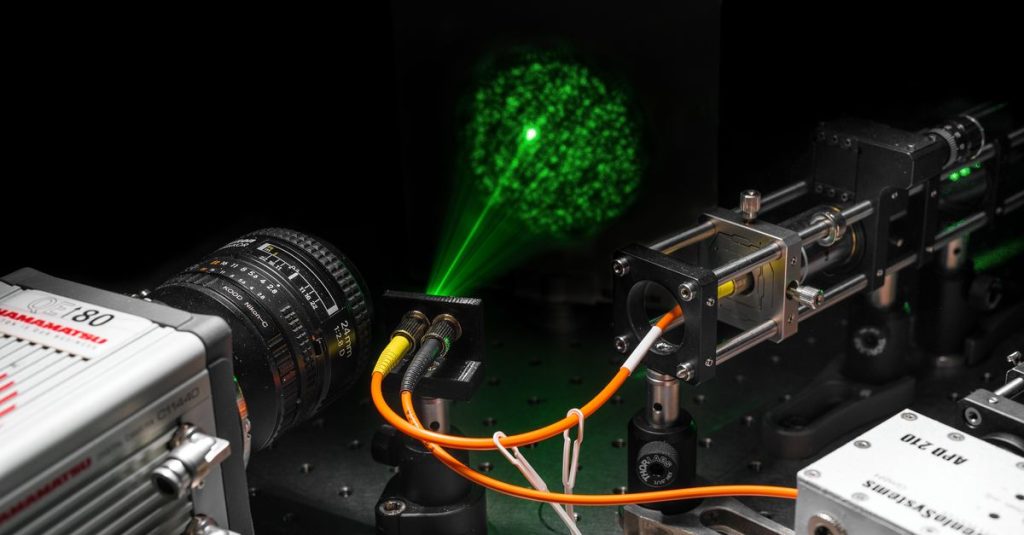

If you want to view the human body or another hard-to-reach space, such as an airplane engine, it’s a good idea to keep the camera narrow. Then you need a small access hole and don’t damage too much. That’s why an international research group has developed a technology by which a three-dimensional image can be created using glass fibers the size of a human hair.

The microendoscope prototype can visualize moving objects a few meters away, while it consists of optical fibers 40 cm long and half a millimeter wide. The researchers showed that they could create depth images as quickly as video by capturing five frames per second. They demonstrated this by picking up, among other things, hand-waving and approaching five. Images are pixelated and depth is indicated by a color scale; A blue object in the distance and the hand approaching the high five turned increasingly red. These results Thursday afternoon in Science.

For small endoscopes that also provide information about depth, there are industrial and medical applications. “For example, a doctor can examine roughness within organs, which may indicate the presence of cancer cells,” says physicist Dan Stlinga, who conducted this study at the University of Glasgow. He has been working at TU Twente for several months now. “And in aircraft engines, information about surface roughness is important to prevent turbulence.”

pulsating headlight

During testing with the prototype, the researchers sent light pulses through one of the optical fibers. This results in a kind of pulsating light that shines over objects in front of the camera. The second fiber measures the amount of light reflected from objects. The 2D image is reconstructed based on the amount of reflected light. The distance to objects (depth information) is determined using lidar technology, which looks at how long it takes for light pulses to return.

The smallest commercially available endoscopes are 0.5 to 1 centimeter thick. This is because they are made up of bundles of thousands of optical fibers. This is necessary because only one type of light can be transmitted through the fibre. That’s why you need a separate wire for each pixel in your image. The researchers circumvented this in their prototype using so-called multimode fibres. “It’s a little bit thicker, but it suits many types of light,” says Stlinga. “The drawback is that the light is scattered into multi-pattern fibers; it’s like looking through a sugar cube. You see the light coming, but you can’t see exactly where that light is coming from.”

Recognizable picture

However, the researchers were able to create a recognizable image because the fibers always scatter light in the same way. This allows them to correct it. “Right now, this patch only works if you don’t bend the fibers,” Stellinga says. “Because you want to be able to move and rotate the binoculars, the search for a better solution is still ongoing.”

In addition to bendability, depth accuracy must also be increased. “We are now seeing differences in depth of up to 2 mm. To be medically relevant, that would have to be 0.1 mm or less.” The researchers also hope to reduce the microscope from two to a single fibre-optic one.

Physicist Johannes de Boer of Vrije Universiteit Amsterdam, who was not involved in the study, calls it an “interesting mix of technologies” and stresses that depth resolution still needs 10 to 100 times better for biomedical applications. “Lighting efficiency should be greatly improved,” he wrote via e-mail. So there are still a number of hurdles that must be overcome before an accurate endoscope can be used.

“Total coffee specialist. Hardcore reader. Incurable music scholar. Web guru. Freelance troublemaker. Problem solver. Travel trailblazer.”

More Stories

GALA lacks a chapter on e-health

Weird beer can taste really good.

Planets contain much more water than previously thought